The Kistler Group will showcase its test and analysis systems for threaded joints at the 2019 Fastener Fair in Stuttgart from 19 to 21 March. Visitors to stand 862 in hall 1 can inspect Kistler’s wide-ranging portfolio of testing and quality assurance solutions for the entire value chain, from development and production through to deployment in manufacturing. This is Kistler’s first appearance at the international exhibition for the fastener and fixing industry.

Fastener assembly has to meet demanding requirements for quality and productivity – and this calls for continuous monitoring and testing of the tools and fasteners that are deployed. Kistler, a leading provider of solutions to enhance quality and boost efficiency, offers an extensive portfolio of testing and analysis systems to achieve this goal. At the Fastener Fair in Stuttgart, Kistler will showcase three solutions used for testing and inspection throughout the production chain: the Vibration Test System (a laboratory test stand), Analyse Basic (the easy-to-use inspection system) and INSPECTpro (the portable measuring instrument). Kistler’s stand will also feature its flexible NCFH NC joining system.

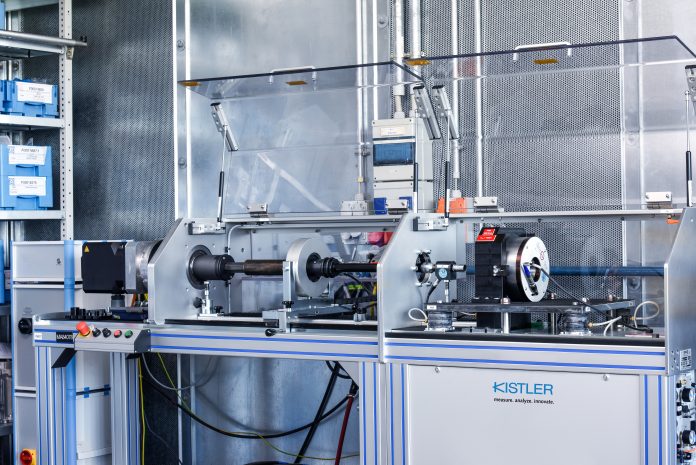

For laboratory applications: the Vibration Test System

Kistler’s fastener test stand provides dynamic testing of the securing behavior of threaded joints, compliant with internationally defined standards. With this system, users in R&D as well as quality assurance can test out real load cases. To achieve this, test objects are inserted into special backlash-free fixtures and are then subjected to loads of up to 50 kN, transversely to the fastener axis. Stroke, test frequency and amplitude can all be adjusted while the Vibration Test System is in operation.

All the functions of this standalone system can be monitored and controlled via the integrated testXpert software. If required, a friction coefficient test can also be integrated – a key quality assurance factor, especially in the automotive and rail sectors. Kistler’s laboratory system comprises a low-maintenance mechanical assembly with drive units, together with sensors for preloading force and thread torque.

For straightforward testing: Analyse Basic with testXpert III

Kistler’s trade show stand will feature a product specifically intended for fastener manufacturers, coating providers and end users who test according to defined standard requirements: Analyse Basic, a system that makes norm-compliant testing simple – just a few clicks are all that’s needed. The system allows ISO-compliant testing of bolts and nuts with torques of up to 500Nm. The integrated testXpert III software is available in multiple languages, and a new version has just been released. The restructured, intuitive user interface and the simple test rig make it easy for new users to start testing: after just one day’s training, operators can use Analyse Basic for efficient, low-cost quality assurance.

For mobile testing: INSPECTpro

A highly flexible range of applications, including quality assurance in goods receiving departments and rapid inspection of fasteners: INSPECTpro can handle them all. This portable system, powered by a rechargeable battery, is connected to Kistler sensor technology to determine the overall coefficient of friction of fasteners. Real-time wireless transmission of the measurands in graphic and numeric form takes place while the test object is actually being tightened, and the data is displayed on the screen. Then, the system automatically determines the overall coefficient of friction, which is also shown on the screen. For advanced evaluation and documentation of measurement results, data can be exported and connected to the testXpert III software. A further benefit: users can configure the system individually with the help of software modules, so they can deploy it for a vast range of other measurement tasks.

Joining instead of threaded connections: NCFH measuring system

As the global market leader in dynamic measurement technology, Kistler also offers measuring systems for other joining methods. One of the Group’s electromechanical joining systems – the NCFH NC joining module – will also be on show at the Fastener Fair. This system, which comprises a hollow shaft drive, offers many outstanding benefits: compact design, excellent dynamics, two available measurement ranges, increased overload protection and a minimal spare parts inventory.

About the Kistler Group

Kistler is the global market leader for dynamic pressure, force, torque and acceleration measurement technology. Cutting-edge technologies provide the basis for Kistler’s modular solutions. Customers in industry and scientific research benefit from Kistler’s experience as a development partner, enabling them to optimize their products and processes so as to secure sustainable competitive edge. Unique sensor technology from this owner-managed Swiss corporation helps to shape future innovations not only in automotive development and industrial automation but also in many newly emerging sectors. Drawing on our extensive application expertise, and always with an absolute commitment to quality, Kistler plays a key part in the ongoing development of the latest megatrends. The focus is on issues such as electrified drive technology, autonomous driving, emission reduction and Industry 4.0. Some 2 200 employees at more than 60 facilities across the globe are dedicated to the development of new solutions, and they offer application-specific services at the local level. Ever since it was founded in 1959, the Kistler Group has grown hand-in-hand with its customers and in 2018, it posted sales of CHF 475 million. About 8% of this figure is reinvested in research and technology – with the aim of delivering better results for every customer.