Removing wipes, rags, plastics, hair and other stringy material at the headworks of a WWTP is very important. A traditional ¼” (6.0mm) screen will remove some of this material but as any operator knows a lot will still pass through a ¼” (6.0mm) screen and will form “mats” (clumps of rags, hair, wipes etc) that will bind pumps and other rotating equipment in the plant. This results in high maintenance costs, and the unpleasant and difficult work required to remove these mats and repair damaged equipment.

The OR-TEC Blue Whale solves this problem. It’s absolutely unique ability to screen to 2.0mm will remove approximately 3x times the volume of these rags, wipes, hair and other stringy material thereby eliminating downstream matting altogether. The OR-TEC Blue Whale Screen is a unique 2.0 mm (or larger) multi-rake screen that is self-cleaning, requires zero wash water or brushes and is guaranteed not to blind. In addition, this precisely engineered screen is the only screen you will need and functions perfectly as the WWTP’s primary and only screen

Due to its unique non-clogging design, the Blue Whale unit is also excellent for screening industrial, food processing or municipal wastewater with high fats, oils, and grease levels (FOG). These high concentration FOG wastes are very difficult to screen and blind most screens. The OR-TEC Blue Whale screen can operate in these types of waste with as low as a 1mm openings protecting pumps and valves by removing this scum while remaining open and clog free.

The superfine (1~5mm opening) mechanical bar screen is suitable for the headworks of both municipal and industrial wastewater treatment plants with over 1,500 units in operation− including over twenty in U.S. Military Bases in South Korea. The screens are manufactured in an ISO 9001 US manufacturing and ISO 14001 environmental standards factory.

OR-TEC / Blue Whale Operation

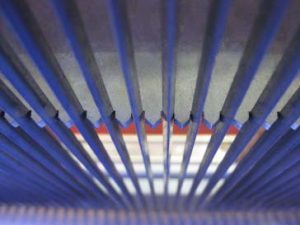

Unlike typical bar screens that use flat bar, which makes the openings between the bars prone to clogging, the Micro Bar Screen uses a parallel array of wedge-sectioned bars (not wedge-wire) with even spaces to form the screen face. Wedge-sectioned screen bars have only 2 contact points on which material can block, as the path from the screen face to the back of the screen is gradually enlarged. Solids which passed through the two contact points cannot become clogged between the wedge shaped bars. A cleaning rake with slotted teeth penetrates well past the opening on the wedge bars−cleaning the screen array and thereby completely preventing clogging or blinding of the screen.

Unlike typical bar screens that use flat bar, which makes the openings between the bars prone to clogging, the Micro Bar Screen uses a parallel array of wedge-sectioned bars (not wedge-wire) with even spaces to form the screen face. Wedge-sectioned screen bars have only 2 contact points on which material can block, as the path from the screen face to the back of the screen is gradually enlarged. Solids which passed through the two contact points cannot become clogged between the wedge shaped bars. A cleaning rake with slotted teeth penetrates well past the opening on the wedge bars−cleaning the screen array and thereby completely preventing clogging or blinding of the screen.

It is typically located in the influent wastewater channel at about a 75°angle. The water flows through the openings between the screen bars while the solids are captured on the upstream side of the screen bars. Captured solids are lifted up to the top of the screen by the travelling rakes, whose penetrating teeth fully clean the openings between the screen bars. These screenings are discharged by a scraper mechanism to a receptacle for disposal or to an OR-TEC Compactor Washer.

This process is mechanically reliable and repeatable, as the entire rake enters cleanly and keeps going timeafter-time. The screen is environmentally efficient as no washwater is needed to keep the screen openings clean−resulting in huge savings in water and electrical usage.

OR-TEC / Vertical Application

Another unique feature of the OR-TEC Blue Whale Screen is its ability to be installed vertically. This allows the unit to operate in applications with deep inverts where an inclined screen will not fit. The vertical screen can also be installed in wet wells and pumping stations to protect pumps.

OR-TEC / Blue Whale Specifications

- Down to 1mm screening

- Self-aligning and self-tensioning cleaning rakes

- Non-Clog performance

- 10 years maintenance free

- Up to 63 mgd (43,750 gpm) per screen

- Guaranteed not to blind

- No rotating brush required for cleaning = no maintenance or replacement of brushes

- Available with Compactor Washer

- Stainless Steel Construction

OR-TEC / Blue Whale Applications

Rittman WWTP (Sterling, OH):

Servicing a municipality of approximately 6,300 customers, the plant was experiencing problems with trash rack bar screens that had 2” gaps which resulted in a deluge of rags in the plant−resulting in the pumps having to be pulled and cleaned monthly. Having researched screen system options via visiting a number of different installations, Ken Mann, Rittman WWTP’s Utility Director, discovered OR-TEC’s Blue Whale at an industry trade show featuring a 3.0mm opening and 2.0 mgd flow/set.

Servicing a municipality of approximately 6,300 customers, the plant was experiencing problems with trash rack bar screens that had 2” gaps which resulted in a deluge of rags in the plant−resulting in the pumps having to be pulled and cleaned monthly. Having researched screen system options via visiting a number of different installations, Ken Mann, Rittman WWTP’s Utility Director, discovered OR-TEC’s Blue Whale at an industry trade show featuring a 3.0mm opening and 2.0 mgd flow/set.

According to Mann, “The results were immediate, as the 3.0mm micro bar screen catches everything from rags to random bi-products, and is then compacted into pellets and goes into a hopper/compressor. Additionally, maintenance is a breeze as all we have to do is occasionally adjust the tension on them.”

Hazlehurst WWTP (Hazlehurst, GA):

With a population of 4,226, the historic small town of Hazlehurst, GA’s Mayor Bayne Stone was looking to replace an old screen that left their WWTP infiltrated with debris materials, which resulted in major plant shutdowns for cleaning. With plans to rebuild the plant in 2017 and a goal of keeping it clean, Stone sought out a solution to the problem at an industry tradeshow. He was provided with a detailed demonstration of OR-TEC’s Blue Whale micro bar screen system featuring a 2.0mm opening and 4 mgd flow/set.

With a population of 4,226, the historic small town of Hazlehurst, GA’s Mayor Bayne Stone was looking to replace an old screen that left their WWTP infiltrated with debris materials, which resulted in major plant shutdowns for cleaning. With plans to rebuild the plant in 2017 and a goal of keeping it clean, Stone sought out a solution to the problem at an industry tradeshow. He was provided with a detailed demonstration of OR-TEC’s Blue Whale micro bar screen system featuring a 2.0mm opening and 4 mgd flow/set.

Impressed with the product, Stone purchased the system and within four weeks it was in operation. Stone noted immediate results, “The turnaround was swift and OR-TEC was excellent at educating us on the product on site before and after the installation. It works great as it solved all of our problems which could have ruined our aerators. It not only removes the larger debris, but even removes the smallest particles like corn kernels.”

Pet Food Care Company (AZ):

The industrial wastewater system for the production of a leading national brand of Cat Food products in Arizona handles a lot of cooked meat products that produce thick, oily run-off with FOG residual debris. OR-TEC provided a self-cleaning, Blue Whale micro bar screen featuring a 1.0mm opening and 0.1 mgd flow/set− processing 50 gpm at 28,000 parts per million TSS, which is mainly FOG.

Jim O’Leary, OR-TEC’s Sales & Marketing Manager, stated, “The Blue Whale system has been operating there to great effect since last year. It doesn’t blind, no washwater or brushes are needed, and it’s virtually maintenance free.”

OR-TEC / Blue Whale Conclusion

According O’Leary, “Ask any operator what their number one headache is and the vast majority will tell you wipes and other rags and plastics causing blockages. It’s a maintenance nightmare. The OR-TEC Blue Whale screen solves this problem, period. Other screens blind or require huge amounts of washwater or have rotating brushes to try to keep the screen face clean. Ours does not. It removes the problem waste that allows mats to form, uses no wash water and will not blind.”

Regardless of the end-use capacity requirement profile, OR-TEC focuses on detailed customization to optimize wastewater treatment needs every step of the way−providing a one-stop service source for the entire life of the system. All OR-TEC’s products are competitively priced and comprehensively backed by a customer service support system that is unparalleled in the industry.

About OR-TEC

Since 1980, OR-TEC has specialized in the integrated manufacture and sales of advanced wastewater treatment equipment for the municipal and industrial marketplace−spanning the U.S., Mexico, Canada, and internationally. The ORTEC team is dedicated to delivering one of the most advanced, reliable product portfolios on the market−featuring a complete line of high quality sludge dewatering, chemical dosing, floatation, screening, and conveying equipment. Innovation, customer-focused service, and site specific customization are the cornerstones that OR-TEC continues to build its reputation upon.