HAAS Schleifmaschinen GmbH in Trossingen, Germany manufactures universal grinding machines which offer significant versatility for full-sequence production of complex, precision tools and workpieces.

Complete processing of large workpieces

Based on requests from customers, we have recognized this for some years, a trend towards complete machining of ever bigger workpieces in one clamping. Manufacturers of large diameter, long length parts with complex, precise features want these large parts processed from one piece, in one clamping, in one machine cycle. Combining multiple operations into a single clamping and into a single machine cycle has multiple benefits; higher overall precision, lower labor and handling costs, fewer number of machines, reduced floor space requirements and faster overall throughput to name a few.

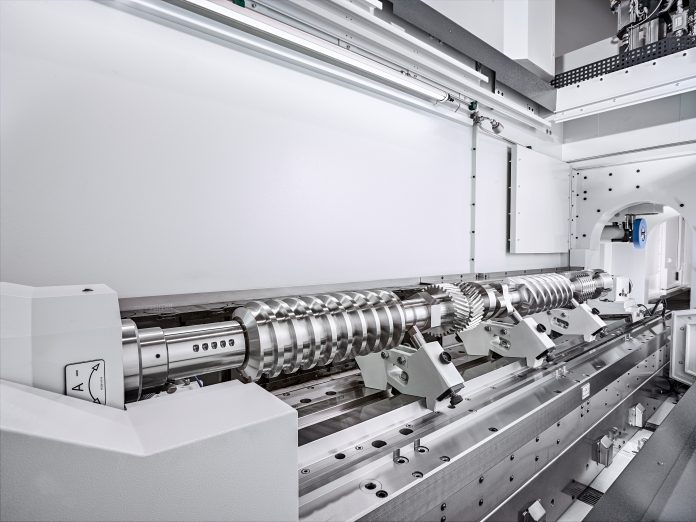

Parts such as hob cutters, broaches, geared shafts, cutting rotors, landing gear components, turbine engine components, winch drives, racks and guideways are ideal candidates for the new high-tech grinding center, where precision, quality and process reliability are paramount.

Precise grinding through stable, symmetrical design, an XL development step in technology

The development of the Multigrind® CB XL model was a challenge for the engineers from Haas Schleifmaschinen because of significantly larger part dimensions and weights. The design task included maintaining “small part” microns accuracy even on larger parts. No small task.

The solution was based on the award-winning, flagship Multigrind® CB, a model designed from the beginning to be adapted and deployed for future demanding grinding tasks. This new CB XL grinding center has much of the same structural design as the CB, but with a “stretched” X-axis and machine table.

Due to its symmetric design, the Haas Multigrind® CB XL maintains stability and rigidity, regardless of part length. The effects of thermal growth are minimized because the grinding contact point is always in the center of the “box” frame. The axis configuration reduces unwanted transitions or vibrations.

The massive mineral cast bed as well as the high-precision linear drive in the machine table ensure stable processes and repeatable grinding results. There is room on the machine table for up to four work supports. Four telescoping doors make for easier loading and unloading and for easier machine set-up.

The massive mineral cast bed as well as the high-precision linear drive in the machine table ensure stable processes and repeatable grinding results. There is room on the machine table for up to four work supports. Four telescoping doors make for easier loading and unloading and for easier machine set-up.

The new Multigrind® CB XL is available in four incremental lengths for workpieces from 1400 to 3200 mm. The modular design also includes options for table extensions which can be configured for the specific requirements of individual customers and applications.

There are many other available components and systems affecting performance and precision the Multigrind® CB XL. Grinding wheel shapes are produced and maintained with on-board dressing spindles and automatic wear compensation, ensuring consistent precision.

Direct-driven, water-cooled grinding spindles are suitable for grinding, milling and drilling. Drive power up to 50 kW [67 HP] at speeds up to 12,OOO rpm deliver high material removal rates. The HSK 80 E interface ensures quick, precise and repeatable automatic wheel change. For most applications the standard tool magazine with up to 15 wheels is enough. Beyond that, Haas offers a shelf tool magazine with space for 65 grinding wheels up to 300 mm in diameter and up to 20 coolant nozzle sets.

Automatic part loading solutions are available, which are fully engineered, deployed and supported by in-house resources.

About Haas Multigrind LLC

Haas Multigrind LLC is the US subsidiary of HAAS Schleifmaschinen GmbH, headquartered in Trossingen, Germany. THIS HAAS is an international system supplier for complex grinding jobs for the tool manufacturing, medical engineering, and aerospace industries. The mechanical engineering firm is specialized in tool grinding centers for complex shapes. The company produces three models of machines, each in a wide variety of different variations: The Multigrind® CA, CB and CU systems. Haas grinding machines are used to manufacture rotary and profile tools, gear cutting and cold forming tools, turbine engine components, medical instruments and implants, and much more. Haas Schleifmaschinen GmbH is the world’s leading supplier of machines for implant manufacturers. The very modern software Multigrind® Horizon is an intuitive, geometry-based grinding program that opens up new horizons in terms of user-friendliness, transparency and performance. It benefits the user both during the design phase and while they are working on the machine.