Movitec working together with EAM-Mosca, offers great potential for both companies to provide comprehensive end of line packaging solutions to new customers in new markets in the US, Canada, Mexico and Latin America.

While it’s vital to weigh critical factors when choosing stretch wrapping, strapping, or both, the union between EAM-Mosca and Movitec is a potentially shapeshifting event for improving packaging processes in the manufacturing industry.

Who is Movitec?

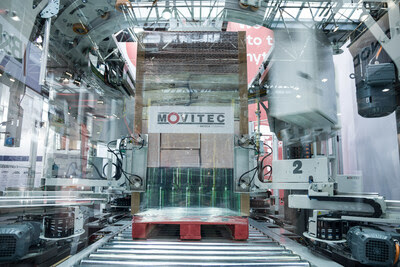

Movitec, a trailblazing manufacturer of pallet rotary ring stretch wrapping machines, stands out for its unwavering commitment to delivering top-quality products and services. With Mosca’s recent acquisition of Movitec, the stretch wrap system provider has solidified its position as a market leader, offering comprehensive end-of-line solutions.

Movitec, founded in 2003 and headquartered in Alcoletge, Spain, has 60 employees and has been offering rotary ring stretch wrap solutions to Spain and the surrounding European countries since then. They install approximately 75 machines per year and currently have 700 machines installed and running in the field. After working on several projects together with Mosca Direct Spain, Mosca acquired Movitec in March of 2021 with one common purpose, to provide best-in-class, fully automated solutions for fast and reliable securing of goods for transport at the end of the packaging line.

The team at Movitec consists of experts passionate about building long-lasting relationships with their clients. As a state-of-the-art engineering company, they provide high level tailor-made solutions to meet their customer’s specific and unique needs. Movitec is always at the forefront of innovation, constantly researching new materials and technologies to create cutting-edge machines like the following:

Saturn S8: Unrivaled Speed and Efficiency

The Saturn S8 is the ultimate high-speed solution for automatic pallet rotary ring stretch wrapping, boasting an impressive capacity of up to 160 pallets per hour. In addition, the machine is designed for maximum production, with a double unwinder that allows for applying two film turns in a single loop without compromising efficiency or reliability.

Saturn S6: Versatility Meets High Capacity

Engineered for demanding production environments, the Saturn S6 offers a versatile automatic pallet rotary ring stretch wrapping solution with a capacity of up to 120 pallets per hour. Moreover, its innovative ring technology ensures a balanced system with reduced wear and maintenance compared to other wrapping methods.

Saturn S4: A Superior Alternative to Rotating Arms

With a medium capacity of up to 70 pallets per hour, the Saturn S4 presents an excellent alternative to rotating arm wrappers. This machine employs state-of-the-art technology, including electronic tension control and self-adjustment, ensuring optimal load stability and minimal film consumption.

Saturn S2: A Step Up from Turntables

The Saturn S2 can produce up to 45 pallets per hour, making it ideal for markets with low production levels. In addition, the Saturn S2 delivers outstanding load protection, stability, and product presentation as a superior alternative to turntable wrappers or rotary arms.

Rotary Ring Stretch Wrappers: What Sets Movitec Apart

Movitec’s rotary ring stretch wrappers offer several advantages, setting them apart from traditional turntable and rotary arm systems:

- Speed and Efficiency: Rotary ring stretch wrappers wrap loads at a faster pace, making them suitable for high-volume operations.

- Cost-Effectiveness: Movitec rotary ring wrappers use the fewest parts of any ring wrapping design on the market decreasing parts consumption and pre-stretching of film of up to 400% decreases film consumption.

- Flexibility: These machines can accommodate various load sizes and shapes, ensuring a customized solution for diverse product lines.

- Consistent Film Application: Rotary ring stretch wrappers ensure even film tension and precise overlap, resulting in uniform load stability, protection and no breakage of film.

- Pre-stretching of film of up to 400% provides better control of tension without breakages.

- No tails of film are left with this type of wrapper.

- No need for double wrapping (down-top and top-down).

- Wrapping can start at any point on the product which leads to lower consumption of film.

- Real rainproof cycle

- Prioritized Features: Focus on speed, consistency, and flexibility.

- Industry Excellence: Ideal for food and beverage, pharmaceuticals, construction materials, and consumer goods.

Stretch Wrapping and Strapping: When to Choose One or Both?

Discovering the most effective packaging method can be a challenge. However, stretch wrapping and strapping each have distinct advantages and work well in specific scenarios and for particular industries. For some applications though, using both stretch wrapping and strapping provide maximum protection and stability during transport and storage.

The Benefits of Stretch Wrapping

Stretch wrapping is a popular method of securing and protecting palletized products during transport and storage. Some of the advantages of stretch wrap systems include:

- Enhanced Protection: Stretch film protects against dust, moisture, and debris, ensuring product safety.

- Load Stability: The stretch film’s elastic properties help maintain load stability during transportation.

- Adaptability: Stretch wrappers can accommodate a variety of load sizes, shapes, and weights.

- Industry Benefits: Stretch wrapping suits various sectors, including food and beverage, logistics, paper, and pharmaceuticals.

The Advantages of Strapping

Strapping is ideal for heavy, rigid, or irregularly shaped products requiring extra support and securement during transportation and while in storage. Key benefits include:

- High Tensile Strength: Strapping materials offer strong, tight bonds that withstand significant force. Mosca’s SoniXs ultrasonic welding allows the use of PP or PET strapping for better cost options and improving Co2 footprint and sustainability.

- Load Security: Strapping systems ensure heavy or unstable loads remain secure during transit and while in storage.

- Minimal Damage Risk: Strapping reduces the chance of package damage, as it doesn’t apply direct pressure to the products. Mosca’s direct drive technology minimizes product impact when strapping.

- Resource Efficiency: Strapping often uses less material than stretch wrapping, reducing packaging waste and lowering costs.

- Industry Benefits: Strapping works well in industries where secure containment of bulky or heavy items is crucial.

When To Use Both for Maximum Protection and Stability

In some scenarios, combining stretch wrapping and strapping provides palletized products with ultimate protection and stability. Here are five reasons why:

- Maximized Security: Combining stretch wrap and strapping ensures the highest level of security, minimizing the risk of product damage, tampering or loss during transit.

- Reinforced Protection: The dual approach delivers superior protection against moisture, dust, and debris, safeguarding the integrity of your products.

- Efficient Load Containment: Both methods accommodate loads of varying shapes, sizes, and weights, optimizing load containment.

- Damage Prevention: The combination of stretch wrapping and strapping helps prevent package damage by providing external protection and internal support.

- Ideal for Diverse Industries: Combining both methods benefits industries like paper, logistics, food, and chemicals, where secure containment and product protection are paramount.

The Key Takeaway

Mosca’s acquisition of Movitec and EAM-Mosca’s increased product portfolio including Movitec’s line of stretch wrappers, offers a game-changing addition to its packaging solutions. Combining Movitec’s dedication to innovation, customization, and reliability with EAM-Mosca’s extensive customer support network, businesses can optimize their packaging processes for efficiency, cost-effectiveness, and product protection. Furthermore, choosing Movitec over competitors means embracing cutting-edge rotary ring stretch wrappers and committing to customer satisfaction.

According to Movitec co-founder Victor Teixiné, “As part of the Mosca Group, we have the opportunity to benefit from the well-established and proven sales and supply chain structures of a global expert. At the same time, we are excited about bringing together the best of both worlds in end-of-line technology and working together to accelerate the development of innovative solutions.”

Lorenz Hercher, Product/Project Manager at EAM-Mosca adds, “This growth within our company group advances our product portfolio to serve even more end of line applications that require high uptime while appreciating unique project requirements.”

By understanding the benefits of stretch wrapping vs. strapping and exploring the advantages of ring-style stretch wrappers, you can elevate your packaging and make a well-informed decision for your business.EAM-Mosca, a leader in strapping systems, is excited to announce the addition of Movitec rotary ring stretch wrapping machines to its product portfolio. As a Mosca company, Movitec is recognized for its outstanding rotary ring stretch wrappers, providing unparalleled protection and stability for palletized and unpalletized loads.