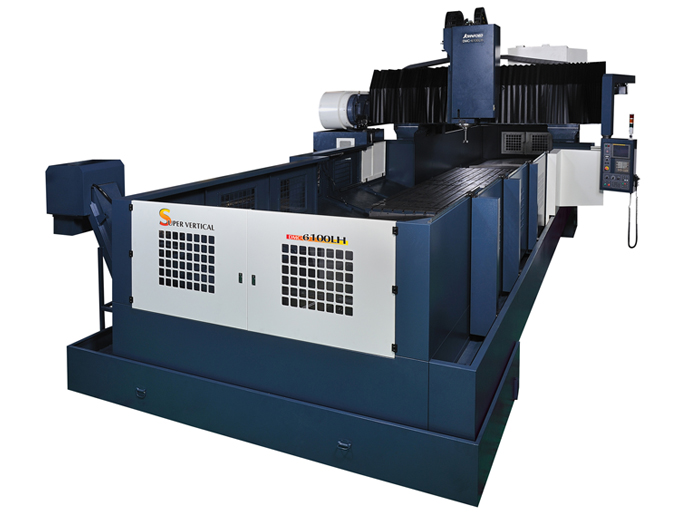

Johnford DMC LH Series double-column moving table bridge mills join the expansive lineup of Johnford double column and sliding double column machining centers, bringing capacity and affordability to large part machining. On display at IMTS 2018 in booth S-338536 by Absolute Machine Tools Inc., the LH series features 110” (2800mm) in Y and 122” (3100mm) to 244” (6100mm) in X in 39.4” (1 meter) increments. Standard Z axis travel is 32” with 42” and 60” optionally available.

Johnford double columns are created from massive Meehanite® iron castings. These bridge mills have a long base casting with complete support of the table over the full X axis travel, allowing massive loads to be machined. The Y and Z axes hold fixed loads at all times while the X-axis carries the only dynamic load, allowing for tight machining and tight tolerances during high-speed machining operations. Because there is no table overhang, X-axis pitch and yaw are eliminated. The spindle centerline-to-column distance is minimized offering further rigidity. The machine’s heavily ribbed cast iron construction provides long tool life and part surface finish. The combination of complete surround table guarding with twin screw-type conveyors and a caterpillar conveyor ensures complete chip removal with little manual cleaning. Additionally, Finite Element Analysis (FEA) is used to design each bridge mill, simulating the effects of real world conditions, including vibration, heat, fluid flow and other physical impacts.

The DMC-3100LH, 4100LH, 5100LH, and 6100LH all feature rigid box ways in Y and Z and Schneeberger roller ways in X for high load carrying capacity. Heavy duty 35HP (50HP opt.) 2 speed gearbox driven spindles provide heaving cutting power and torque. The standard 40 tool ATC (60, 80, 120 opt.) provide fast reliable tool changes.

The DMC LH Series is available in numerous customizable configurations including extended Z axis travels, full automatic 5 face head changing, and full 5 axis. A variety of options are available to tailor the machines to specific applications such as aerospace and mold/die. Fanuc, Mitsubishi, Siemens, Heidenhain, and Fagor controls are available based on customer preference.

About Absolute Machine Tools, Inc.

Absolute Machine Tools, Inc. sells and supports Johnford Bridge & Gantry Mills; You Ji

Vertical Turret Lathes; Tongtai Horizontal Machining Centers (former Hitachi-Seiki

OEM); Quicktech Multi-Axis Multi-Spindle Mill/Turn Centers; Lico Multi-Slide CNC

Screw Machines and Twin Spindle Multi-Slide Mill/Turn Centers; Nexturn Swiss-type

Lathes; AccuteX Wire EDM and Die Sinker Machines; APEC 5-axis Gantry-style Linear

Motor Machining Centers; and Precihole Gundrilling Machines. The company has

worked with several of its principal machine tool partners for over 25 years to offer some

of the most heavy-duty, accurate, and productive machines in the industry. The

company has built its reputation on exemplary applications engineering, service,

customer support, comprehensive training, and effective preventive-maintenance

programs. In addition to its headquarters in Lorain, Ohio, the company has established

direct full-service technical centers in Mason, Ohio; Elgin, Illinois; and Livonia, Michigan.

Absolute Machine Tools, Inc.

7420 Industrial Parkway

Lorain, OH 44053

800-852-7825