In developing the certification of its products, ITG considered various product performance parameters to determine the optimal chemical content for the immersion liquid. To ensure clarity and consistency in the system’s utilization, the company has devised comprehensive guidelines regarding these special components’ design, and their recommended printed circuit board assembly (PCBA) process.

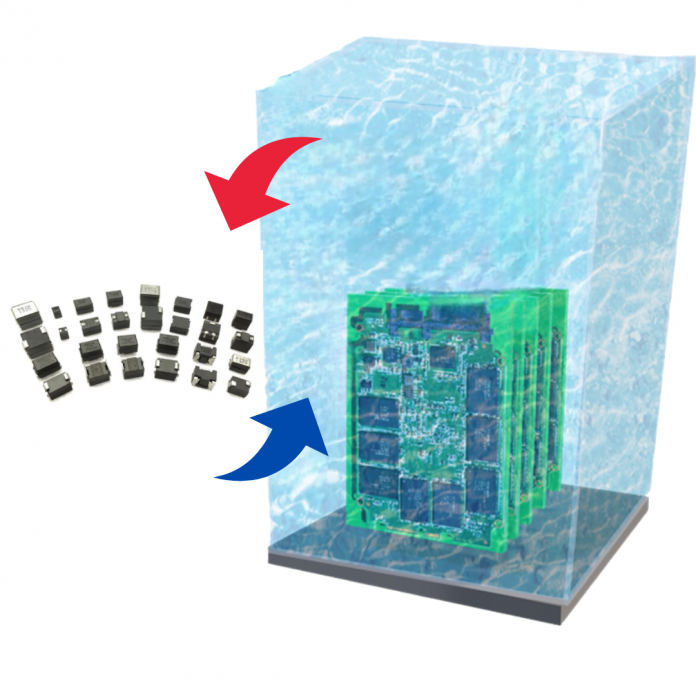

Immersion cooling involves submerging a component in a non-conductive, dielectric liquid, which then absorbs the component’s heat. Because of the liquid’s temperature gradient, the heated liquid – which is naturally less dense – rises to the top. As this occurs, the liquid is removed from the top of the tank and replaced with a cooler liquid from the bottom. Helpfully, immersion cooling does not require additional elements such as fans, which among other benefits improves energy efficiency.

ITG’s wide range of elevated and SMD power bead inductors are designed and developed for high frequency and high performance DC to DC converter application. The company’s power bead inductors are known for reliable performance in high-current multi-phase voltage regulators that power processors and memory modules for servers, graphics cards, storage and data centers.

About ITG Electronics

Founded in 1963, ITG Electronics is a leading electrical and mechanical components supplier headquartered in Elmsford, NY. With a highly experienced engineering team, ITG designs and manufactures high performance magnetic components, modules and EMI filters for a wide range of applications including consumer electronics, automotive, cloud computing, telecommunication, industrial and renewable energy.

ITG factories are IATF/TS16949, ISO9000, ISO14000, OHSAS18000, QC0800000, ISO14064 Certified.