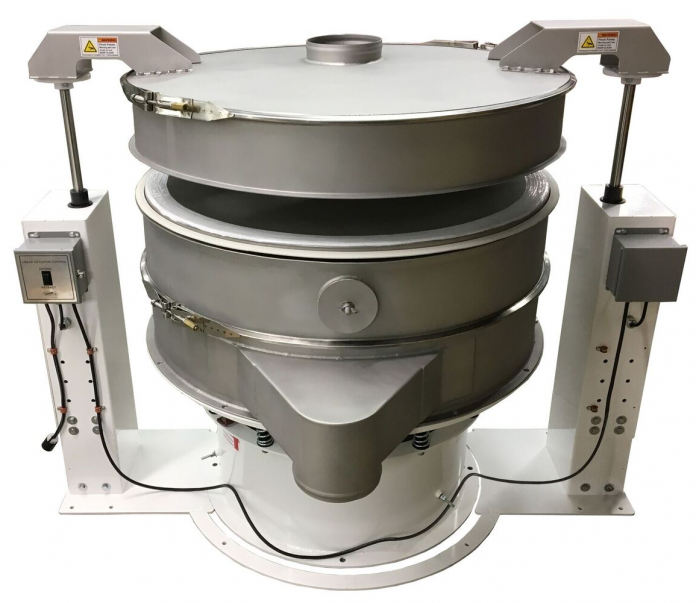

Midwestern Industries, Inc. (Massillon, OH), a leading manufacturing mainstay of innovation for the screening industry since 1953, has recently launched their operator-friendly Electro-Lift separator screen changing system. The revolutionary, ergonomically designed lift system is electrically powered to assist in making separator screen changes easier, faster, and safer. Engineered with a 120 volt sealed gear-driven system, operation is as simple as plugging into any convenient outlet and pressing a switch.

Quality built and engineered in the USA, Midwestern’s Electro-Lift is adaptable to fit a variety of different frame deck configurations. While it is designed to lift the frames of Midwestern Industries’ round separators, most makes and models of competitors round separators can easily convert to this system.

Electro-Lift Ergonomic Difference

The system’s ergonomically designed configuration assists with the lifting of separator frames to eliminate the need for two people to remove each frame–making screen changes virtually a one-man operation. Typically, screens must have hands on them when changing out. However, Electro-Lift is mounted independently to the frame so there is no need for it to be locked out when you are working under them with your hands.

This engineering versatility also allows operators to change screens and gain access to the interior of the unit for cleaning or inspection–which is exponentially faster than using comparable systems. The system can also be used to inspect the screens to ensure quality control. Ultimately, the system changes screens faster with no lifting of heavy frames, which drives the Electro-Lift system’s key attribute of reducing downtime to a minimum.

Electro-Lift Safety Solution

Electro-Lift Safety Solution

Safety is an integral part of the 120 volt Electro-Lift as it leverages a sealed gear-driven system, which ensures the frames will not drift down when changing your screens–even if the power fails. Unlike traditional hydraulic or pneumatic changing systems, if the power does go out during screen changes, the frames will not fall.

Because the unit is 120 volt, it can be plugged into any convenient outlet, which eliminates the need for customers to provide compressed air.

Whereas most competitive versions will use some form of clamping device if power is lost, Electro-Lift uses two mechanical screws powered by the actuator. Additionally, there are no cumbersome hoses to deal with, and the sealed system eliminates the need for greasing which makes it environmentally cleaner.

Electro-Lift Conclusion

The Electro-Lift separator screen changing system is a next-generation solution that is vital for a myriad of processing industry applications including: Pharmaceutical, Food & Beverage, Chemicals, Waste Water, Shot Peening, Plastics, Roofing Granules, Ceramics, and Powdered Metals, amongst others.

The Midwestern Industries’ Electro-Lift is competitively priced vs. traditional alternatives, and delivers the following essential configuration advantages:

- Adaptable to multiple deck configurations.

- Faster screen changes help to reduce downtime to a minimum.

- Sealed gear driven system ensures safe screen changes every time.

- 120 volt electrical can be plugged into any convenient outlet.

- Frames will not fall or come down if power fails during screen changes.

About Midwestern Industries, Inc.

Since 1953, Midwestern Industries, Inc. has been a mainstay of innovation for the screening industry, delivering customized manufacturing and design solutions for a myriad of processing industries including: Pharmaceutical, Food & Beverage, Chemicals, Aggregates, Shot Peening, Plastics, Brick and Clay, Ceramics, and Powdered Metals, amongst others. Known throughout the industry as “The Sizing People®”, Midwestern’s comprehensive product line offers advanced application solutions for handling coarse, fine, wet, and dry materials with the ability to screen and separate particles from 20 microns and up. We achieve these demanding standards by leveraging advanced precision manufacturing screening techniques and accessories that drive productivity.

Midwestern Industries, Inc.

P: 877-4-SIZING | (877) 474-9464)

Midwestern Contact

Jay Nagy / Advertising Director

jnagy@midwesternind.com

P: (330) 837-4203

Editorial Contact

Ray Farrar / Method Media LLC

rayf@methmedia.net

P: (216) 861-0862